As an Engineer, I get a lot of questions about how I chose this job. I became interested in the electric utility industry as a kid. Both my father and my maternal grandfather were farmers and ranchers who have held board positions at a REA. It is what made me aware of the electric utility industry in the first place.

I wanted to go to college and be able to find a good job in a rural area after graduation and ideally, one near where I grew up.

Rural public power districts and cooperatives are well known throughout the country for having good paying jobs with good benefits, and for hiring engineers.

To become an engineer at a utility, I attended the University of Nebraska at Lincoln Engineering College. I was lucky enough to have an internship for Nebraska Public Power District working at their natural gas power plant in Beatrice during its construction. During my senior year of college, I studied for and passed an eight-hour engineering exam called the Fundamentals of Engineering. This test is a requirement to become an “EIT” or “Engineering in Training” under the Nebraska Board of Architects and Engineers.

After graduation, I accepted a full-time position as a Distribution Staking Engineer with NPPD in Kearney. I worked there for four years under the tutelage of a few Professional Engineers, which is a requirement to become a Professional Engineer. I was then able to take and pass another eight-hour exam called the Professional Engineering Exam, as well as an Engineering Ethics exam. This was my final step to becoming a Professional Engineer.

Electrical Engineers in the electric utility industry do quite a few things. We’re responsible for designing the power lines, substations, power plants and equipment that make the electric grid work.

We run power flow and load growth studies to help predict where system upgrades will be needed.

We run safety analyses like Arc-Flash studies and Spill Protection Plans to help keep other employees like lineworkers and electricians safe.

We run economic analyses to determine the most cost-effective ways to provide power, helping keep rates lower. We participate in standards committees to help develop safety rules for the National Electric Safety Code and National Electric Code.

Being an engineer at a rural public power electric utility is interesting and rewarding. You get to be a Jack of all trades. Every day, I’m working on a variety of projects with different employees.

Since I’ve been the Engineering Manager at Dawson PPD, the Engineering Department has accomplished quite a few things.

Dawson PPD has moved to a more modern mapping system. We’ve started designing and building our own large distribution and transmission projects. We implemented a more thorough substation testing and maintenance plan. We’re developing our own Arc Flash Studies and Spill Protection Studies. We implemented a new load management system along with an accompanying text messaging system for customers.

Hopefully Dawson PPD’s General Manager will continue to have me here for years to come. Dawson PPD is a great place to work and central Nebraska is a great place to live!

OTHER NEWS

Dawson PPD’s board is preparing for the future

At the September board meeting, Dawson Public Power District directors reviewed the July financial records. Both operating expenses and revenue are below budget. Due to strong financials in earlier months, the year-to-date net margin is ahead of budgeted projections....

New Maintenance Truck Style Joins Dawson PPD Fleet

The iconic red truck of our maintenance lineworkers remains in Dawson PPD’s fleet, but with a twist.

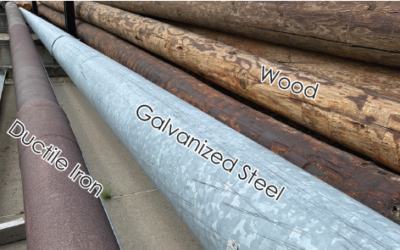

Guest column: Common types of utility poles

Utility line poles have evolved significantly. From simple wooden poles to materials like fiberglass, concrete and ductile iron, these poles have adapted to the changing needs of our industry.