Selling corn ethanol is a competitive business. It’s essentially the same product no matter who makes it. How can one company stand out from the rest? The answer: efficiency.

KAAPA has invested nearly $50 million in its Ravenna facility to improve efficiency – and the investments are paying off. Today, the company is one of the leading suppliers of ethanol for Western markets.

“In a commodity business, it makes sense to be the most efficient producer and to serve your customers well,” explained Mitch Feldman, KAAPA Ethanol Ravenna Plant Manager. “The state of California pays a premium based on how environmentally friendly each gallon of ethanol is. KAAPA is where we are today because of the steps we have taken to improve our overall efficiency; from the electric energy used to the amount of time producers spend delivering corn to the plant.”

Nebraska is the nation’s second largest ethanol producer, according to the Nebraska Ethanol Board. The state’s 25 ethanol plants have a total production capacity of more than two billion gallons annually.

The Nebraska Corn Board states that the amount of thermal energy required to make a gallon of ethanol has fallen 36 percent since 1995, and electricity use is down 38 percent. At the same time, producers are squeezing 12 percent more ethanol out of every bushel of corn.

By improving the facility’s energy efficiency, KAAPA Ethanol Ravenna has increased its ethanol production since 2017 from 88 million gallons to over 130 million gallons annually without increasing its electric use.

The plant uses over 70 million kilowatt hours of energy annually and is the largest electric consumer for its provider, Dawson Public Power District. The annual energy used by KAAPA Ethanol Ravenna is the equivalent to more than 6,100 homes.

Working together with Dawson PPD, KAAPA Ethanol Ravenna has made several energy efficient improvements that have qualified for rebates under the EnergyWise program. The EnergyWise program is sponsored by Nebraska Public Power District in partnership with its wholesale utility customers. The goal of the program is to reduce overall energy use at the commercial, agricultural and residential levels for a cleaner energy future.

“The rebates have made the difference between a project that may get done and a project that will get done,” Feldman said. “These upgrades have made us one of the most efficient ethanol plants in the nation in terms of thermal energy.”

The first EnergyWise rebate occurred in 2014 with the improvement to the facility’s cooling system. When making ethanol, maintaining optimal temperature is key to a high-quality product. The overhaul of the existing equipment saved an estimated 4.5 million kilowatt hours in seven years.

The second incentive involved a new air compressor system to power tools, control systems, and machinery. Before 2020, KAAPA Ethanol Ravenna had two smaller air compressors. After one failed, the facility invested in upgrading to one large system with variable frequency drives and saved about 790,000 kilowatt hours annually.

The most recent incentive occurred in 2021 and was one of largest energy efficient investments to date. KAAPA Ethanol Ravenna replaced its chillers with a new cooling tower. By investing in this improvement, the facility is estimated to reduce its electrical energy use by one million kilowatt hours annually, the equivalent to the electrical use of 85 homes.

“We are glad to work with Dawson PPD,” Feldman said. “They understand that reliable electrical power is important for our business. We don’t have a big green button to push after a power outage; it’s not easy to start and stop production. Dawson PPD understands that and has made improvements to our service to ensure that interruptions are kept to a minimum.”

Ethanol is considered to have a positive energy balance. According to the United States Department of Agriculture, one British Thermal Unit of energy in the production of corn ethanol production results in 2.3 BTUs of usable energy in the form of ethanol. The improvements in overall technology, in addition to some strategic energy efficient upgrades, have helped KAAPA Ethanol become a leader within its industry.

Sources:

KAAPA Ethanol Ravenna

KAAPA Ethanol Ravenna is located just over a mile east of Ravenna and is electrically served by Dawson Public Power District.

KAAPA Ethanol Ravenna Chiller

KAAPA Ethanol Ravenna replaced its chillers with this new cooling tower in 2021. By making this investment, the facility is estimated to reduce its electrical energy use by one million kilowatt hours annually.

Mitch Feldman, KAAPA Ethanol Ravenna Plant Manager

Mitch Feldman, KAAPA Ethanol Ravenna Plant Manager, (right) discusses the facility with Dawson PPD Lineman Jerry Folck from the top of its largest grain bin.

OTHER NEWS

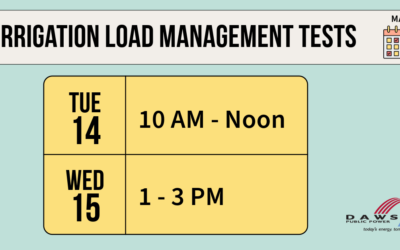

Short load control tests planned in May

Irrigation load management tests scheduled for May 14 & 15, 2024

Dawson PPD Board Members vote on the level of on-peak irrigation demand

Dawson PPD May 2024 board meeting summary

Take control of your finances with Budget Billing

Known as “budget billing,” Dawson PPD implements a fixed budget based off your account’s last 12 months of billing history from May to May of each year.