As a not-for-profit utility, Dawson PPD focuses on cost-effectively extending the life of its existing facilities while maintaining adequate levels of safety and reliability. Testing wooden poles helps the District ensure reliability and long life of its equipment, saving customers money in the long run.

Traditionally, pole testing involved a hammer for sounding, a shovel for digging around the base and drilling holes to test for decay. Today, Dawson PPD hires a contractor that uses a scientifically-based system called POLUX as a less-invasive and more accurate form of testing.

POLUX works by sending two, three inch long probes the size of an eight-penny nail into the base of the utility pole. This is the most vulnerable point where decay is most likely to occur on a pole. The probes measure resistance and moisture content of the pole. This information, along with the type of wood the pole is made of and how it was treated are run through a computer program with the pole’s GPS location recorded.

Typically, Dawson PPD uses a Southern Yellow Pine tree for its poles, which should have a resistance of 8,000 pounds per square inch when new. If the measurement falls below 50 percent of the recommended resistance, in this case 4,000 PSI, the pole is marked for replacement.

All of Dawson PPD’s poles are tested every 10 years on a rotating schedule with 10,000-11,000 poles tested annually.

OTHER NEWS

Please move over for emergency and utility crews

If you see police, firefighters, utility crews or other emergency personnel on the side of the road, please slow down and move over when possible. Together, we can keep our crews safe. May 2018

Help us, help you: Please update your contact information

In order to best serve you, please make sure that Dawson PPD has the most up-to-date information related to your account. Some situations that may warrant an update include: Switching from land line to cell phone New cell phone number New email address New last name...

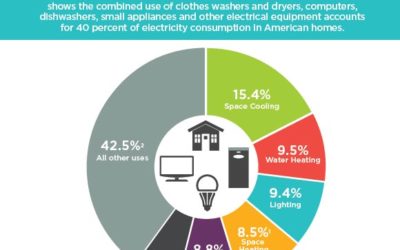

How to choose efficient appliances that save money

When it’s time to replace a large appliance in your home, be sure to take a moment and consider what you will purchase. Dramatic advancements in the efficiency of many electric appliances provide the same level of end-user comfort with substantially less...